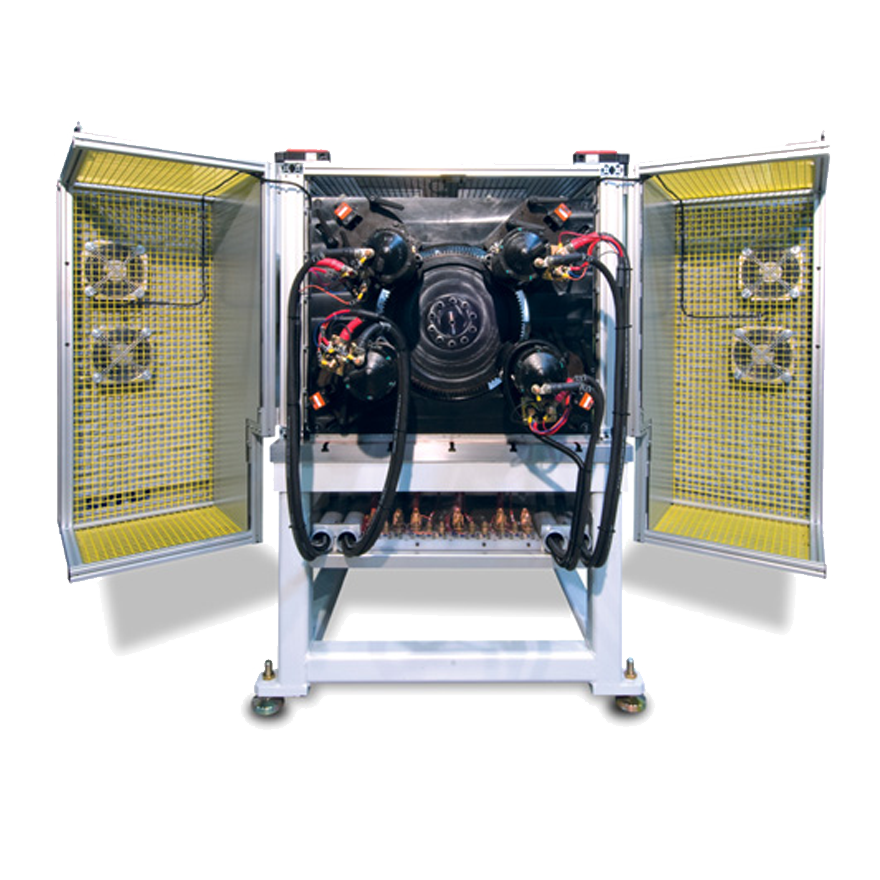

ST-66G2/ST-69G2 Engine Simulator Testing

Our ST-66G2 and ST-69G2 Engine Simulators are designed for accelerated starter durability testing. The simulators replicate the speed pulsations the starter experiences from the engine’s piston strokes during cranking and engine starting.

These testing systems provide a repeatable and consistent testing platform that is used for component design validation and premature failure investigation.

Tests four starters with separate and unique crank profiles, the ability to test Start/Stop and Change-of-Mind (CoM) Starters, an actual engine flywheel can be used to better simulate live engine cranking Programmable power supply provides an accurate simulation of battery internal resistance, automated testing with programmable scripting, and provides simulation of engine firing sequence.

Features

- Cranking Profile Generator Software for creating speed profiles, or users can import profiles from recorded engine speeds for precise engine simulation

- Eliminates the issues and costs of live engine testing: fuel cost, handling, maintenance, safety, exhaust emissions and environmental issues

- Execute cranking profiles while monitoring starter speed, torque, current and voltage Capability of mixing cranking simulation tests with multi-point performance evaluation Integrated engine flywheel emulates the mechanical engagement conditions with axial and radial starter position adjustment systems

- Capable of testing Start-Stop and Change-of-Mind (CoM) starter motors with programmable cadence, and ability to engage moving flywheel

- Simulates engine Cranking Profiles from two to sixteen cylinders

- Computer controlled test bench with programmable power supplies that provide an accurate simulated internal battery resistance

- Can accommodate single solenoid, dual solenoid, tandem solenoid, magnetic and locomotive switch connection starters

- Programmable power supply voltage with high-speed switch 1 and switch 2 timing for precise energizing control of the solenoid

- Durability and stress testing of starter components including gear systems, starter drive clutches, and pinion shift levers

- Each starter can have multiple unique profiles loaded that can be run in a customizable order for testing over a wide range of test conditions

- Over speed (over-run) testing function for the simulation of the engine running with the starter engaged

- Starter and solenoid temperature monitoring via thermocouples or RTD with automated cooling fan control

- Advanced reporting and statistical capabilities records cranking and performance reports at programmable intervals

- Provides a consistent and repeatable test environment to emulate application problems such as extended cranking, user abuse, leakage or hydraulic lockup in cylinders. Scripting of test procedures provides customization of testing process

- Engine wear simulation capability by dynamic modification of the cranking profile

- Up to 6 programmable flywheel stop positions for replication of flywheel gear and pinion wear characteristics

Options

- Pinion travel distance measuring for capturing data at retract and extended positions

- Laser-based high speed pinion speed measurement for Change-of-Mind testing